Microsynthetic polypropylene (PP) fibers are no longer a commodity

PP fibers require performance specifications in order to reduce the expected plastic shrinkage cracking in concrete

The objective of this paper is to address the effect of fiber properties, specifically, tensile strength and modulus of elasticity (elastic modulus), on the performance of synthetic microfibers with respect to their ability to reduce plastic shrinkage cracking in concrete.

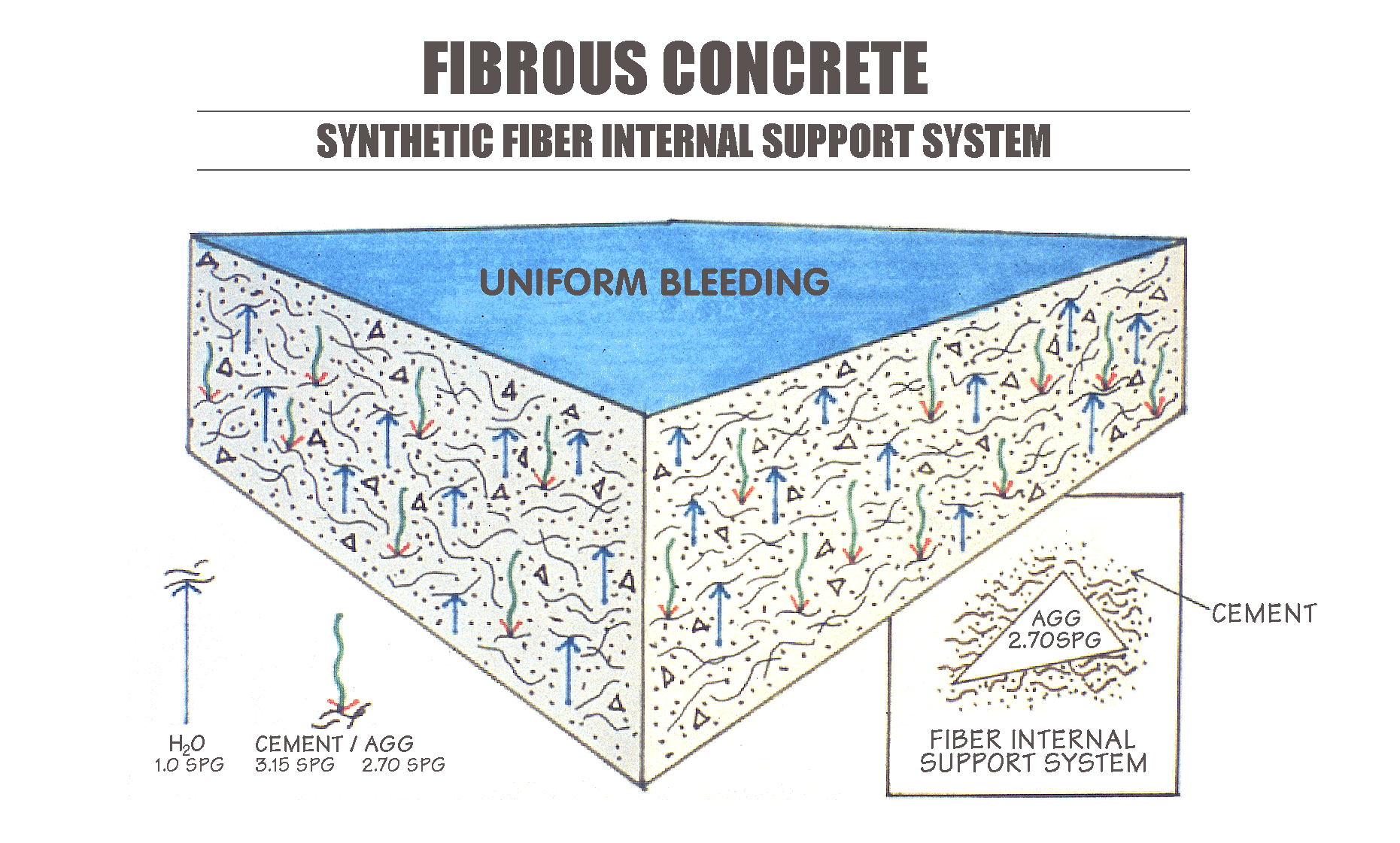

Plastic shrinkage is the shrinkage that takes place before cementitious systems such as concrete set. Without proper protection, concrete may crack due to plastic shrinkage. Protection includes measures that are taken to prevent premature drying of the concrete surface, such as fogging and the application of an evaporation reducer, and the use of synthetic microfibers. These fibers reinforce plastic concrete and provide crack control against low tensile stresses that develop in the unhardened concrete due to plastic shrinkage.

Synthetic microfibers are made from different materials such as polyolefin (typically, polypropylene, high-density polyethylene), polyvinyl alcohol and nylon, and they are available in different shapes and sizes (diameter and length). Several reports are available in literature on the effects of synthetic microfibers on plastic shrinkage behavior. A general observation is that a finer fiber is more effective in reducing the width of plastic shrinkage cracks than a coarse fiber ACI 544.5R-10, "Physical Properties and Durability of Fiber-Reinforced Concrete.") In addition, most fine-diameter microfibers with a high specific fiber surface area have been found to be particularly effective in reducing plastic shrinkage cracking.

Comprehensive investigations on the effect of several fibers on the plastic shrinkage cracking characteristics of concrete have been conducted by Naaman and his colleagues. As reported in ACI 544.5R-10, the fibers evaluated included polypropylene, polyvinyl alcohol, high-density polyethylene, Spectra, carbon, and steel. The testing parameters covered a wide range of fiber properties, including diameter, length, cross-section, form, bond strength, and elastic modulus. Though they were test variables, the tensile strength and elastic modulus of the fibers that were investigated also varied, ranging from that for the synthetic materials to that for steel.

The data showed that volume fraction and diameter of fiber reinforcement are the two most influential parameters that control plastic shrinkage cracking in concrete. For a given volume fraction of fibers, changing the fiber length or aspect ratio did not have a noticeable effect on plastic shrinkage cracking. Decreasing the fiber diameter or equivalently increasing the number of fibers crossing a unit area, however, did significantly improve the control of plastic shrinkage cracking.

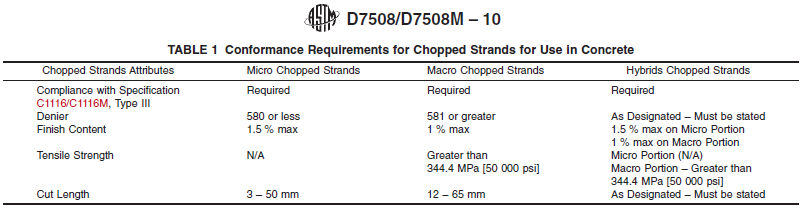

As stated earlier, the fibers tested in the investigations reported in ACI 544.5R-10 had a wide range of tensile strengths and elastic moduli. However, the data show that tensile strength and elastic modulus are not factors in controlling the plastic shrinkage cracking of concrete. Consequently, in Table 1 of ASTM D 7508/D 7508M, "Standard Specification for Polyolefin Chopped Strands for Use in Concrete," there is no tensile strength requirement for polyolefin-based microfibers, while there is a minimum requirement of 344 MPa for polyolefin-based macrofibers (see excerpt below). In addition, ASTM D 7508/D 7508M has no elastic modulus requirement for polyolefin-based fibers, micro or macro.